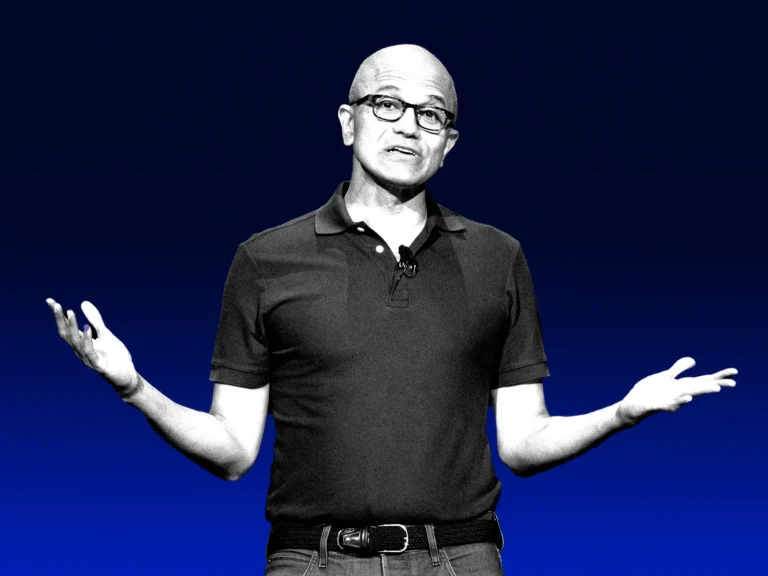

Jensen Huang says if ‘anything were to happen’ in Taiwan, Nvidia could have GPUs made somewhere else

TSMC makes Nvidia’s GPUs. Without this partnership, the flow of these crucial AI chips would slow or stop.

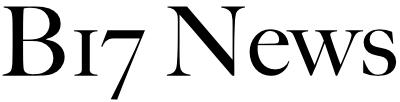

When Nvidia CEO Jensen Huang spoke with Goldman Sachs CEO David Solomon on Wednesday, the banker raised this relationship — and how precarious it is as tensions rise in the Taiwan Strait.

“The majority of your supply-chain partners operate out of Asia, particularly Taiwan,” Solomon said. “Given what’s going on geopolitically, how are you thinking about that as you look forward?”

Huang replied that if TSMC were compromised, supply would continue — though it wouldn’t be as good.

Nvidia owns “enough intellectual property” that “in the event that we have to shift from one fab to another, we have the ability to do it,” Huang said, referring to the huge fabrication facilities where semiconductors are manufactured.

Most of the world’s chip companies, and several tech giants, rely on TSMC to do the hard and complex work of making these components at a massive scale. Its location on the island of Taiwan, which China claims, puts a huge question mark on the tech industry and AI’s future.

Last year, Huang said he felt “perfectly safe” relying on manufacturing in Taiwan. On Wednesday, he got more specific.

“Maybe the process technology is not as great. Maybe we won’t be able to get the same level of outperformance or cost, but we will be able to provide the supply,” the Nvidia CEO said. “In the event anything were to happen, we should be able to pick up and fab it somewhere else.”

Still, Huang described TSMC as the best chip manufacturer in the world by an “incredible margin.”

A monumental task’

There aren’t many other options for Nvidia in terms of manufacturing partners. Samsung and Intel are some of the few other companies capable of making the most powerful chips, and Intel’s manufacturing prowess has been questioned intensely in recent years.

“Picking up and moving to a new supplier would be a monumental task, and the capacity would take many years to rebuild,” Dylan Patel, the chief analyst at SemiAnalysis, told B-17. “This is not something that could be done on a short time scale by any means.”

Chris Miller, the author of “Chip War,” concurred. “The key unasked question is the time horizon,” Miller said. “How long would it take to bring supply online outside of Taiwan? A couple years at least.”

B-17 asked Nvidia to clarify whether Huang’s statements meant that if TSMC’s main fabrication sites went down for any reason, supply could flow continuously, and, if so, from where. An Nvidia spokesperson offered no additional comment beyond Huang’s statements on Wednesday and pointed to regulatory filings that describe the company’s supply chain.

“While we work to enhance the resiliency and redundancy of our supply chain, which is currently concentrated in the Asia-Pacific region, new and existing export controls or changes to existing export controls could limit alternative manufacturing locations and negatively impact our business,” Nvidia said late last month in a filing with the Securities and Exchange Commission.

A regulatory filing early this year said Nvidia got its wafers, the ultrathin slices of (usually) silicon that make the core of its high-powered chips, from TSMC and South Korea’s Samsung. Though Samsung has some of the capabilities required to produce the most advanced chips, TSMC is the clear leader.

Fabless risks

It’s hard to overstate how important TSMC is to the semiconductor industry.

How much of its production output the Taiwanese firm assigns to each of its customers is an important indicator that financial analysts use to assess how much revenue so-called fabless chip firms, which design chips but don’t make them, can generate.

TSMC is also responsible for the most advanced manufacturing involved in Nvidia’s newest Blackwell chips, the delay of which has been the subject of much market consternation.

TSMC is building a chip factory in Arizona as part of an effort to diversify its global footprint away from China-Taiwan tension. But this facility isn’t expected to produce cutting-edge semiconductors, especially at first. Building chip fabs takes years and billions of dollars.

“TSMC Arizona is definitely going to be used by Nvidia,” Patel said.

Huang praised TSMC for scaling up to meet the demand that created Nvidia’s “hockey stick” earnings in recent years.

“We use them because they’re great,” Huang said, “but if necessary, of course, we can always bring up others.”